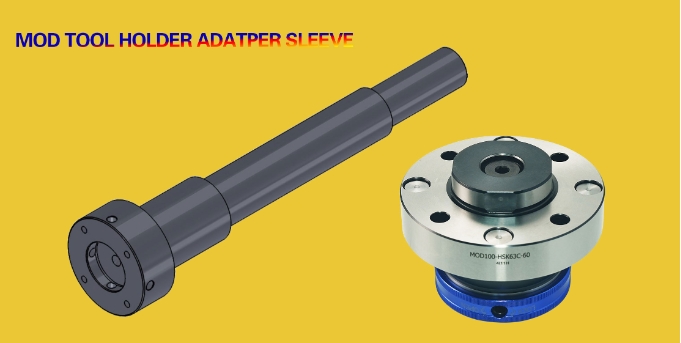

Tool Holder Adatper Sleeve : a flexible sharp tool in machine tool processing In the field of machining, with the diversification, modularity, and increasingly high precision requirements, flange conversion tool holder as an efficient and flexible conversion tool, with its unique design and versatility. This paper will introduce the application scenario, design principle and characteristics of flange conversion tool holder in order to provide reference for the machining industry.

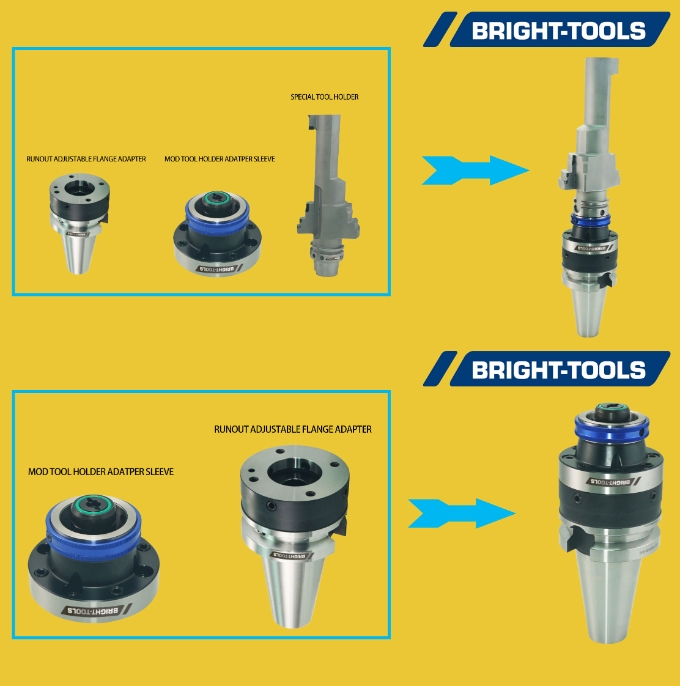

Bright-tools CNC, the application scenario Machine tool spindle installation Tool Holder Adatper Sleeve can be easily installed on the machine tool spindle (with flange connection design), as a bridge between the machine tool and the tool. This feature enables the machine tool to easily adapt to various types of cutting tools to meet different processing requirements. In addition to the machine spindle, the flange conversion tool holder can also be installed on the flange tool holder, further expanding the processing capacity of the machine tool. This installation method allows the machine tool to tool holder more complex processing tasks, improving processing efficiency and flexibility. Used as a fixture In some specific cases, the flange conversion tool holder can also be used as a fixture to fix and clamp the workpiece or tool. This function further broadens the application range of flange conversion tool holder, making it more practical in machining.

Bright-tools CNC, the design principle The flange conversion tool holder is designed to fully consider the requirements of accuracy and stability.

Its main design features are as follows: Radial Concentricity Adjustment Adjust the flange conversion tool holder through the positioning screw on the machine spindle or zero adjustment tool holder. This design ensures that the knife tool holder can maintain a high degree of stability and accuracy after installation, thus meeting the requirements of precision machining.

Axial jump adjustment

Further improve machining accuracy, the flange conversion stem is equipped with thrust plates and positioning screws on the mounting flange. By adjusting these components, the fine-tuning of the axial beating can be achieved to ensure the stability of the tool during machining.

Bright-tools CNC features Convert the different cone tool holders The flange conversion tool holder can convert different cone tool holders, which allows the machine to easily adapt to many types of tools. This feature greatly improves the compatibility and flexibility of the machine tool, and meets the requirements of different processing tasks. After converting different cone tool holders, the flange conversion blade tool holder can still maintain high accuracy. By adjusting the positioning screw and thrust plate, the accuracy can be further fine-adjusted to ensure the processing quality. This feature gives the flange conversion stems a significant advantage in the field of precision machining.

Bright-tools CNC conclusion In conclusion, the flange conversion tool holders play an important role in machine tool processing with their unique design and versatility. It can easily fit many types of tools, improve the compatibility and flexibility of machine tools, and to ensure machining quality and accuracy.

With the continuous development of machining industry, the application prospect of flange switch tool holder will be broader. In the future, we can expect more innovative designs and features to be introduced into the flange conversion tool holders to meet the more complex and diverse processing needs.

Bright-tools is an enterprise focusing on high-end precision manufacturing, with 17 years of rich experience and profound technology accumulation.

With technological innovation and high-quality product service as the core, the company is committed to providing users with high-quality, cost-effective CNC tool holders, CNC accessories, tools, etc., and has been sold to 57 countries and regions, and is deeply trusted and praised by customers!

Bright-tools has the world's leading tool holders production base and inspection and testing center, and its manufacturing strength is in the forefront in China. Our core production and testing equipment include TAKISAWA, Doosan, HAIMER, Dieblod, ZEISS, ZOLLER, etc.

According this equipment further ensures our superior production efficiency and product quality.

We use advanced robotic automated production lines to ensure the stability of product quality and greatly improve production efficiency. At the same time, we use MES system, ERP system and OA office system to carry out comprehensive production management and enterprise resource planning, realizing the intelligentization of production and management, thus greatly improving the operation efficiency.

The Bright-tools always adheres to the concept of "technology and quality", and is committed to providing customers with high-quality products and services. We look forward to working together with you to contribute our full strength and enthusiasm to the cause of intelligent manufacturing.